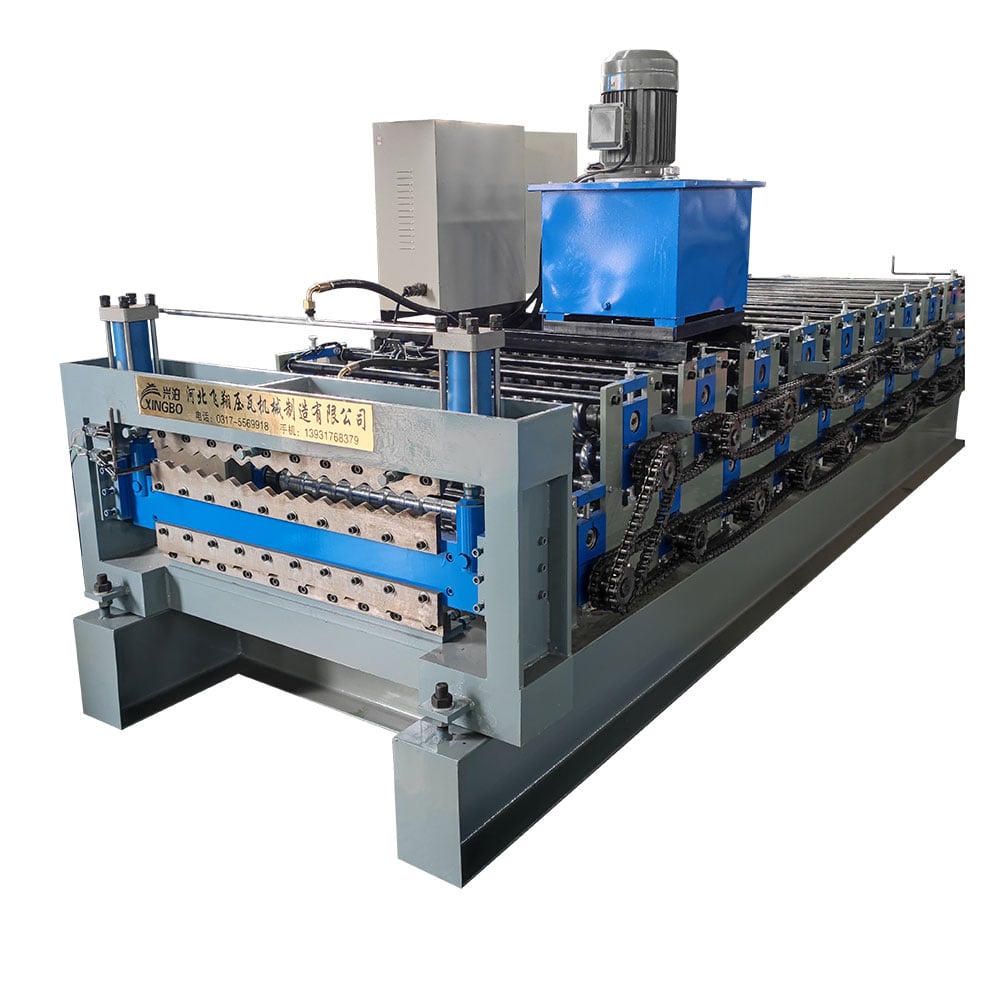

Double Layer Roll Forming Machine: A Comprehensive Guide

Introduction

A double layer roll forming machine is a versatile piece of equipment used in the manufacturing industry. It is designed to form metal sheets into various shapes and profiles with precision and efficiency. This article will provide a comprehensive guide to double layer roll forming machines, exploring their features, applications, benefits, and considerations for choosing the right machine.

What is a Double Layer Roll Forming Machine?

A double layer roll forming machine is a type of roll forming machine that has the capability to produce two different profiles simultaneously. It consists of a series of rollers and dies that progressively shape the metal sheet as it passes through the machine. The machine is equipped with two sets of rollers, each set dedicated to forming a specific profile. This allows for increased productivity and flexibility in the manufacturing process.

Features of a Double Layer Roll Forming Machine

A double layer roll forming machine offers several key features that make it a valuable asset in metal fabrication:

- Dual Profile Capability: The ability to produce two different profiles simultaneously enables manufacturers to optimize production efficiency and reduce costs.

- High Precision: Double layer roll forming machines are designed to ensure precise shaping and forming of metal sheets, resulting in consistent and accurate profiles.

- Customizability: These machines can be tailored to meet specific manufacturing requirements, with adjustable settings for profile dimensions, angles, and lengths.

- Automation: Many double layer roll forming machines are equipped with advanced automation features, such as PLC control systems and touch screen interfaces, to streamline production processes and reduce manual labor.

- Enhanced Durability: These machines are built with robust materials and components to withstand heavy-duty usage and ensure long-term reliability.

Applications of Double Layer Roll Forming Machines

Double layer roll forming machines find wide-ranging applications in various industries, including:

- Construction: These machines are used to manufacture roofing sheets, wall panels, and other structural components for buildings.

- Automotive: Double layer roll forming machines are utilized in the production of automotive body parts, such as fenders, chassis components, and door frames.

- Appliances: They are employed in the manufacturing of appliance components, such as refrigerator panels, air conditioner enclosures, and washing machine drums.

- Furniture: These machines are used to produce various furniture components, including metal frames for chairs, tables, and cabinets.

- Storage Systems: Double layer roll forming machines are utilized in the fabrication of shelving systems, racking systems, and storage containers.

Benefits of Using Double Layer Roll Forming Machines

The adoption of double layer roll forming machines offers several advantages for manufacturers:

- Increased Productivity: The ability to produce two profiles simultaneously significantly enhances production efficiency and reduces cycle times.

- Cost Savings: By eliminating the need for separate machines for each profile, manufacturers can save on equipment costs, floor space, and maintenance expenses.

- Improved Quality: Double layer roll forming machines ensure consistent and precise shaping of metal sheets, resulting in high-quality profiles with minimal defects.

- Flexibility: These machines can be easily adjusted to accommodate different profile specifications, allowing manufacturers to respond quickly to changing market demands.

- Reduced Material Waste: With precise control over the forming process, double layer roll forming machines minimize material waste, leading to cost savings and environmental benefits.

Considerations for Choosing a Double Layer Roll Forming Machine

When selecting a double layer roll forming machine, manufacturers should take into account the following factors:

- Production Requirements: Assess the desired production capacity, profile complexity, and material specifications to ensure the machine can meet the specific needs of the manufacturing process.

- Machine Size and Configuration: Consider the available floor space and the layout of the production facility to determine the appropriate size and configuration of the machine.

- Automation and Integration: Evaluate the level of automation required and the compatibility of the machine with existing production systems.

- Quality and Reliability: Choose a reputable manufacturer that offers high-quality machines with reliable performance and after-sales support.

- Cost Considerations: Compare the upfront cost, long-term maintenance expenses, and return on investment to make an informed purchasing decision.

Conclusion

Double layer roll forming machines are essential tools for manufacturers in various industries. Their ability to produce two profiles simultaneously, coupled with their precision and flexibility, makes them invaluable for increasing productivity and reducing costs. When selecting a double layer roll forming machine, it is crucial to consider production requirements, machine size, automation features, and overall quality. By investing in the right machine, manufacturers can optimize their manufacturing processes and stay competitive in the market.